CT-4008T-5V12A (4 Range)

High precision and multi range Battery tester

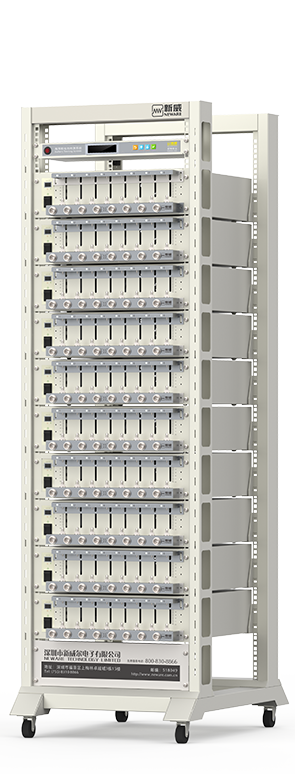

CT-4000-5V6A is Neware one of the best selling models which is widely used in cell manufactuers, universities and labs worldwide. It's great for testing different sizes of cylindrical, pouch and coin cells. Neware has launched new CT-4000-5V6A with three output current ranges which can improve the testing accuracy based on varying charging/discharging current. Each CT-4000-5V6A has 8 channels, and each channel is indepent. Working with Neware powerful software, it can be your best partner in the daily test.

Specs

Keep improving and lead the market.

-

500msMin. Pulse Width

500msMin. Pulse Width -

≤1msResponse Time

≤1msResponse Time -

0.05%Accuracy

0.05%Accuracy -

DCIRTest

DCIRTest -

Multi-range

Multi-range -

10Hz/100HzData Acquisition Frequency

10Hz/100HzData Acquisition Frequency

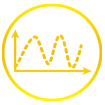

CT-4000-5V6A with Three Output Current Ranges

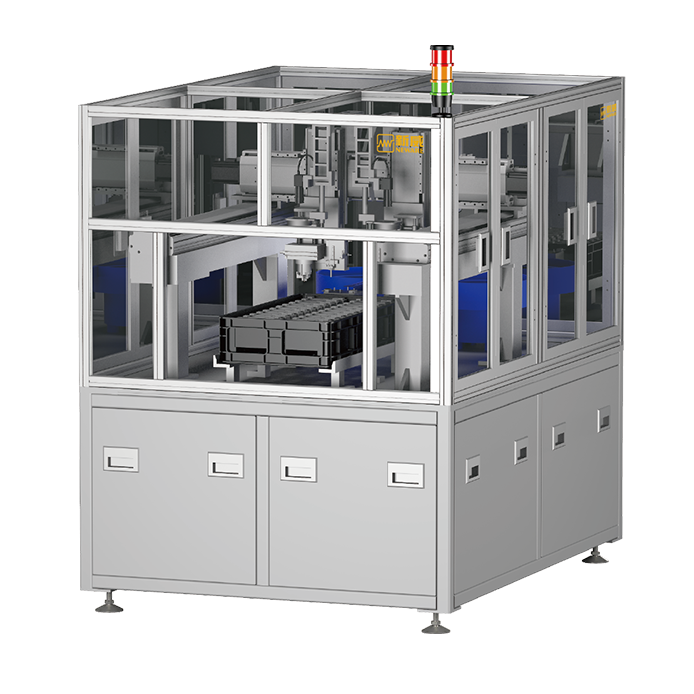

To meet the various requirements adopted in advanced battery research, our equipments can automatically switch the current range in accordance with user settings to maintain consistent accuracy, and can be fitted with additional hardware to provide a number of optional features and capabilities. The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard. The accuracy for current and voltage on these channels is ±0.05% FS.

Discover the difference between 5V6A and 5V12A

在外观尺寸相同的情况下,仅从航插和通风设计可以区分开来。

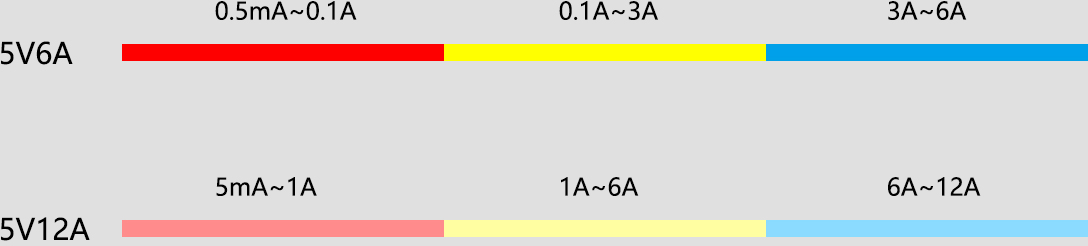

5V6A uses one fan, but 5V12A uses two.

Air intake on the right or left side

The inventive heat-radiating system is practical and feasible and can increase heat-radiating efficiency and space utilizaion rate. Each CT-4008-5V6A supports from one to eight test channels, depend on the application.Each test channel is operated independently. This allows different tests to be performed on different test channels simultaneously, with tests being started independently, or in a block.

Square Air Outlet

Compared with 5V6A, 5V12A uses two square fans for dissipating heat. Industrial design is delicate.

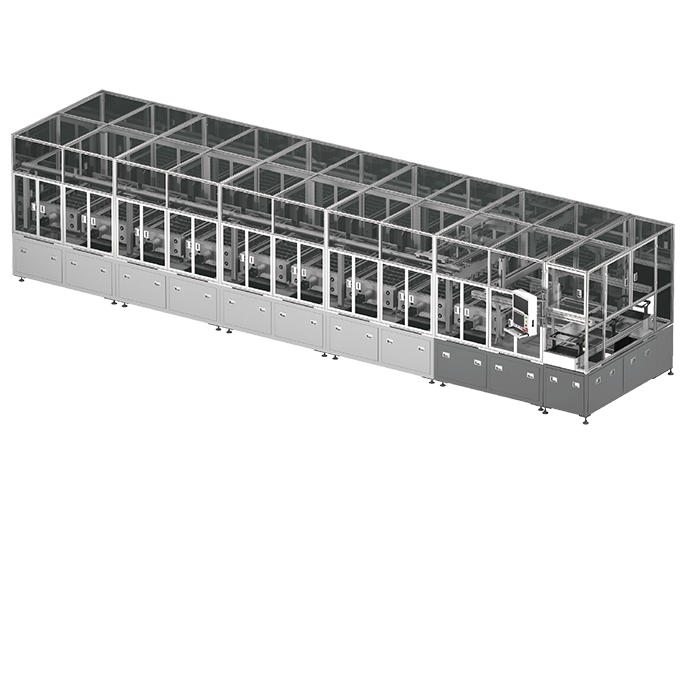

CT-4008T-5V6A battery testing system combined one middle machine, which can work with up to 10 sets of 5V6A equipments. What's more, you can use one gantry to DIY a new equipment. The most surprising thing is that it can save much more floor space.

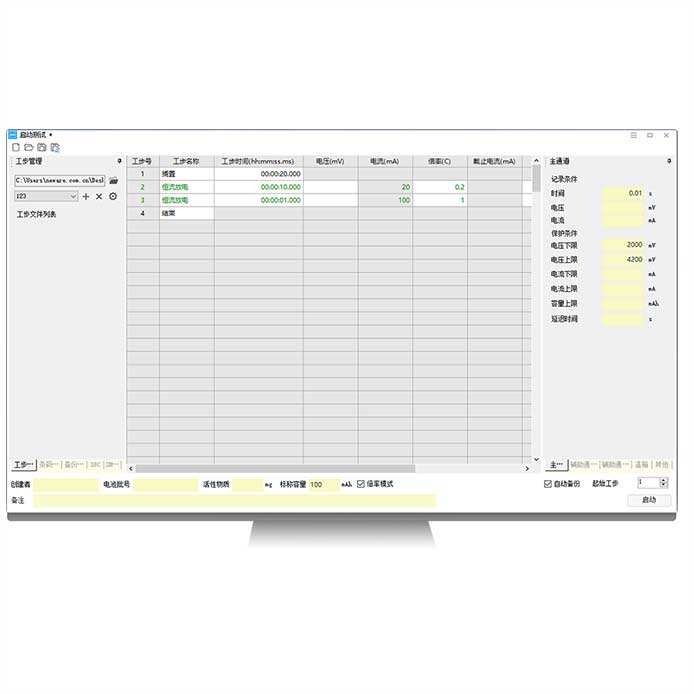

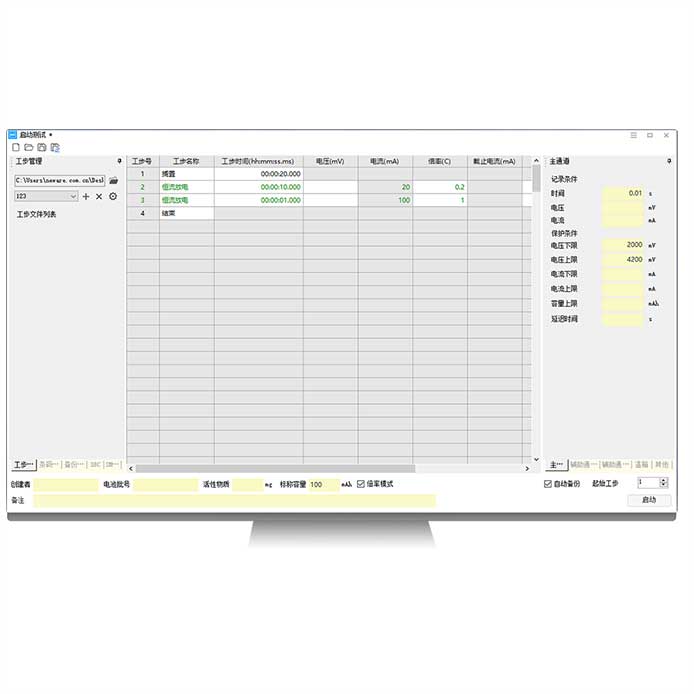

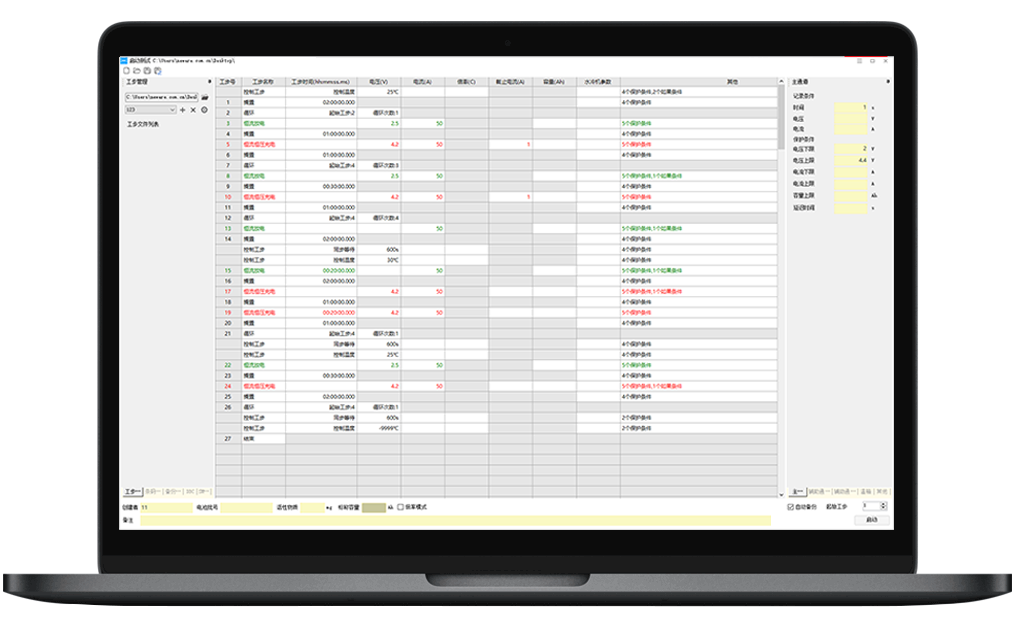

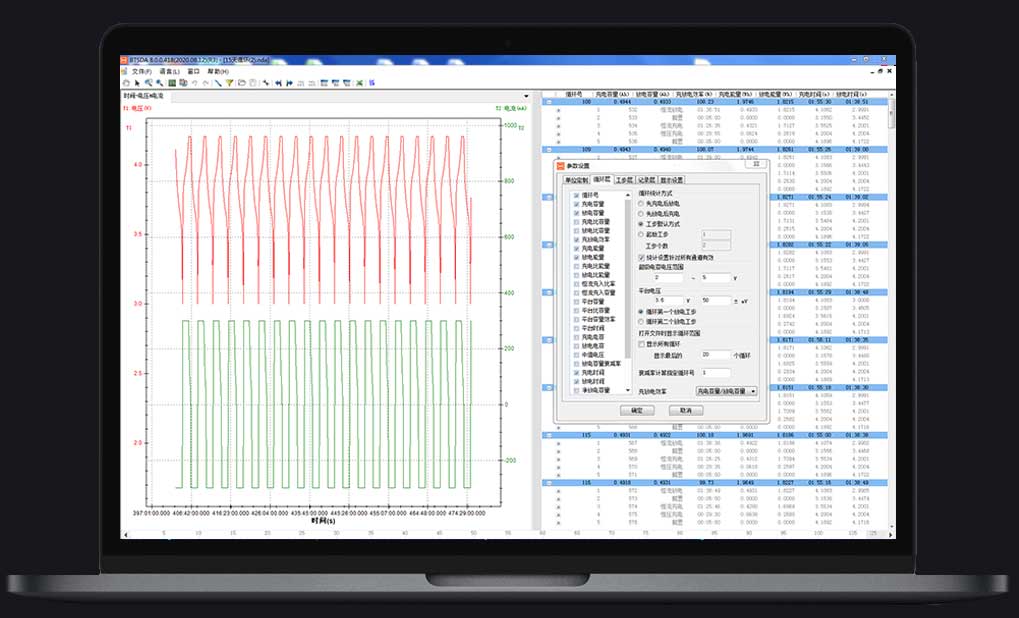

Integrated operation and collaborative work through BTS upper computer control system

NEWARE battery charge and discharge test system realizes integrated operation and collaborative work through BTS upper computer control system, so as to maximize the battery characteristics and functions.

Software

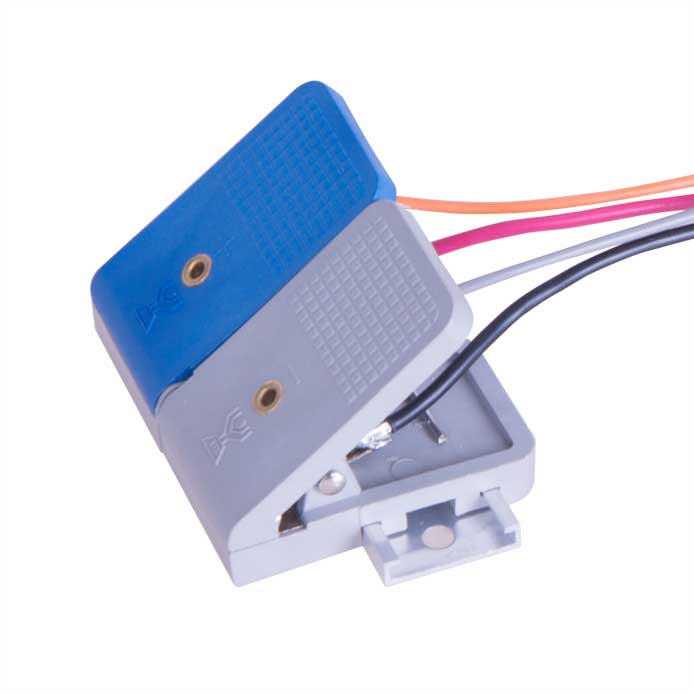

Essential components

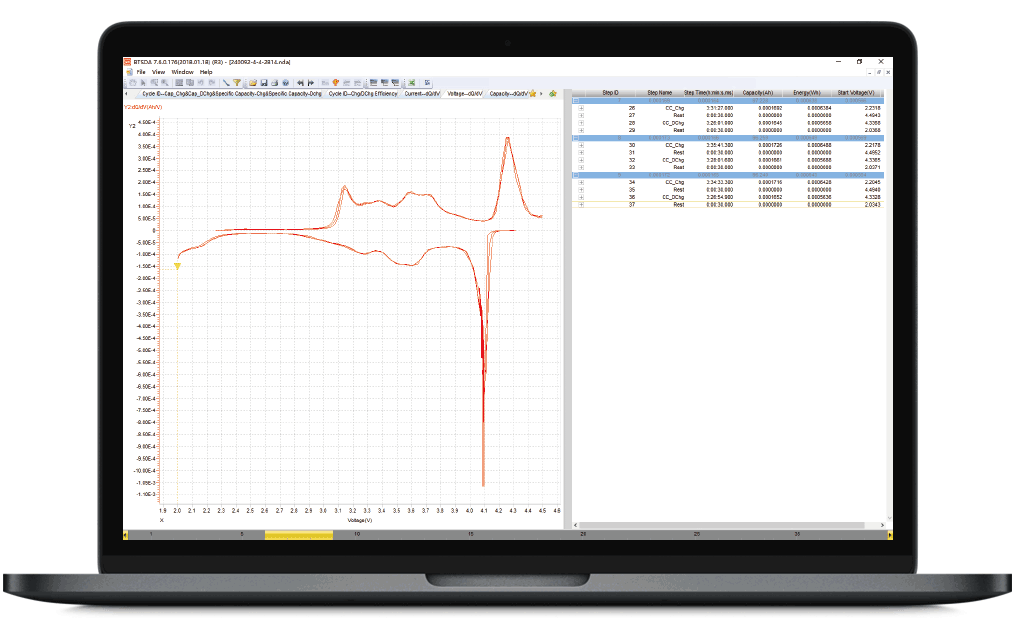

dQ/dV

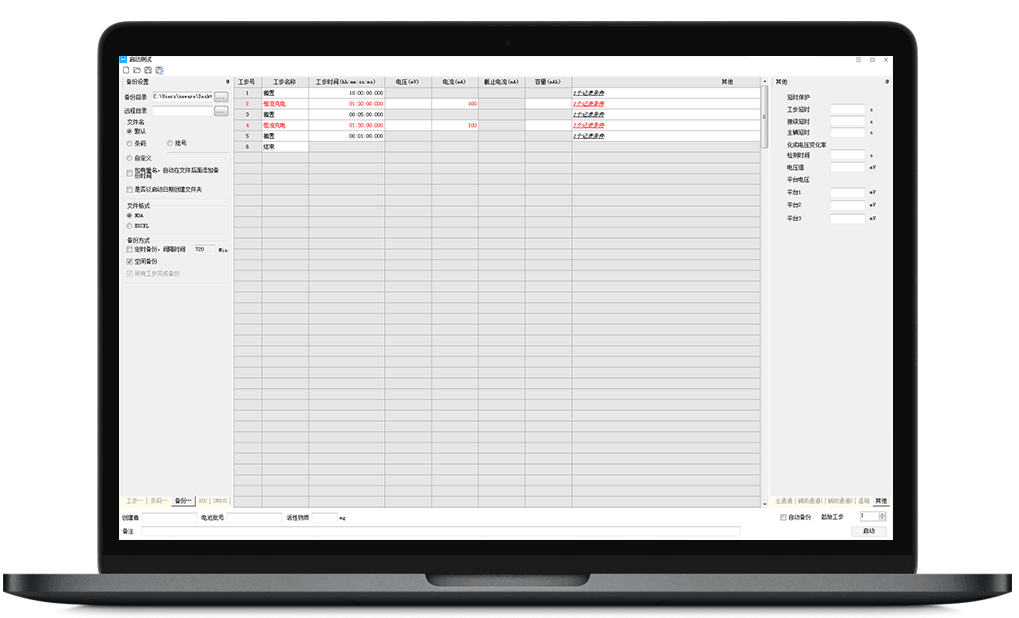

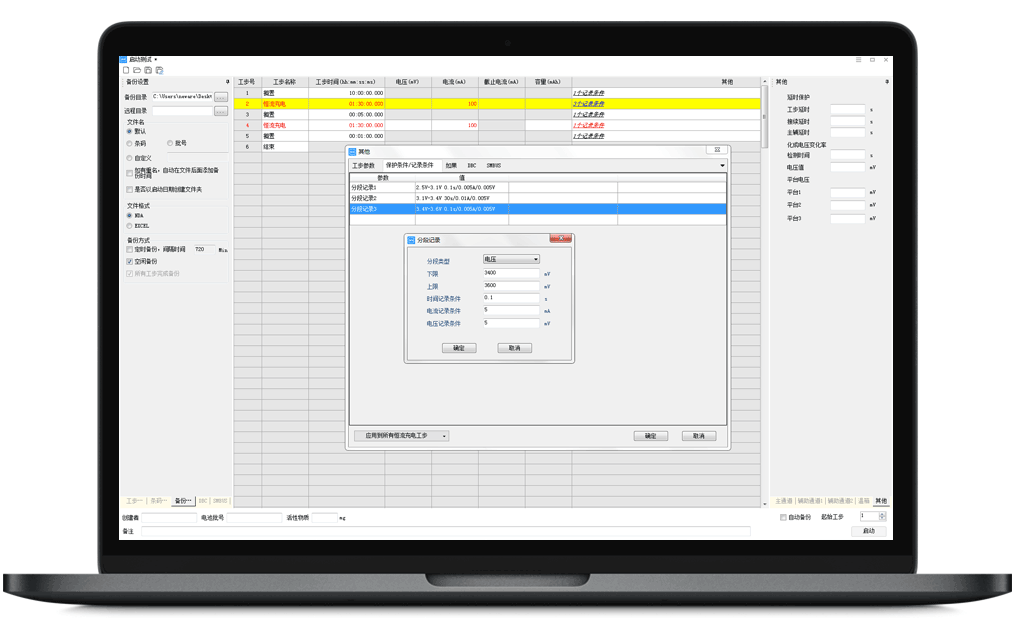

Conditions Switches

Segment-Record Conditions

Control peripheral equipment by communication

EDLC Testing

dQ/dV differential capacity curve: the peak on the curve indicates that there is a voltage plateau on the charge and discharge curve, and different peaks represent different electrochemical reactions.

Battery testing steps need to be estimated for several conditions according to different operations during testing applications; Conditions switches meet requirements for multi-exits programming types. “And””or” logic operation, “≥”, ”≤”, ”=” comparatively calculate; Time duration ”t”, can achieve control requirements for special testing. Every step supports 5 condition switches; Support multi-exits, go to any steps, achieve more flexible process control.

Data record settings for voltage, current and time are supported; 3 segment-record conditions can be set for each step; Every segment can be set: ΔT, ΔV and ΔI .

BTS Server come true the peripheral equipment (Battery tester & Automation) communication control via switch.

The unit of Q is Coulomb, 1 Coulomb = 1A * 1s = 1As; 1Ah = 3600 As(Amp Second); Work voltage U = Charge upper limited voltage - Discharge bottom limited voltage; Working voltage can be set and the EDLC coulomb could be calculated automatically by the software.

Application

Good news for lithium battery manufacturers

-

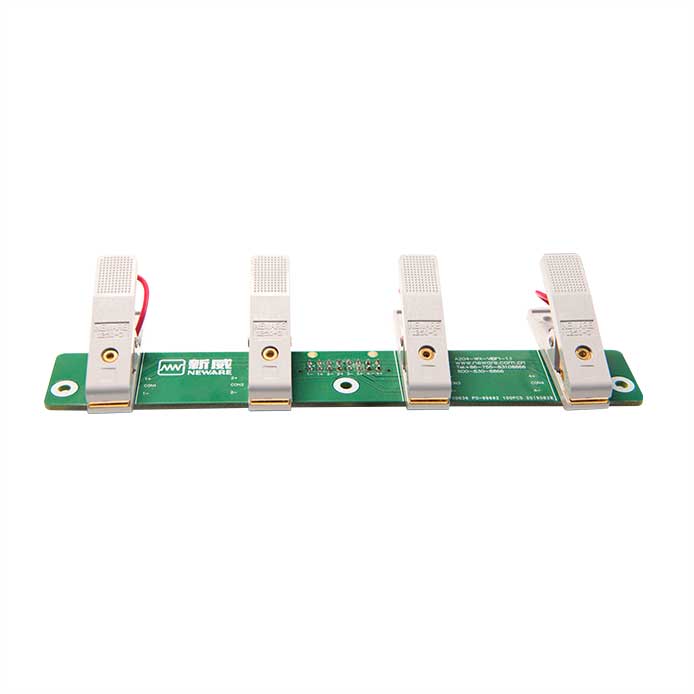

Polymer Pouch CellUsing polymer clamps to test, such as 6545 polymer clamp.

-

Cylindrical CellThe upper and lower clamps of Neware 5V6A and 5V12A tester can move up and down accurately according to the scale marked on the left and right sides. The cylinder battery is tested between the upper and lower clamps.

-

SupercapacitorUsing polymer clamps to test, such as 6545 polymer clamp.

Customer Site

Global - English

Global - English