-

Volume, size and weight

-

Nominal Internal Volume150L

-

Inside DimensionsW500 mm×D500 mm×H600 mm

-

Overall DimensionW750 mm×D1500 mm×H1750 mm (Without Bulge)

-

WeightAbout 260kg

-

Performance

-

Testing Methods

GB/T 5170.2-2008 Temperature Test Equipment

GB/T 5170.5-2008 Damp and Heat Test Equipment

-

Temperature Range-20℃~150℃

-

Temperature Fluctuation≤1℃(No Load and Stable Temperature)

-

Temperature Deviation±2.0℃ (No Load and Stable Temperature)

-

Heating Time-20℃→+150℃ ≤60 min (No load, average nonlinearity)

-

Cooling Time+20℃→-20℃ ≤45 min (No load, average nonlinearity)

-

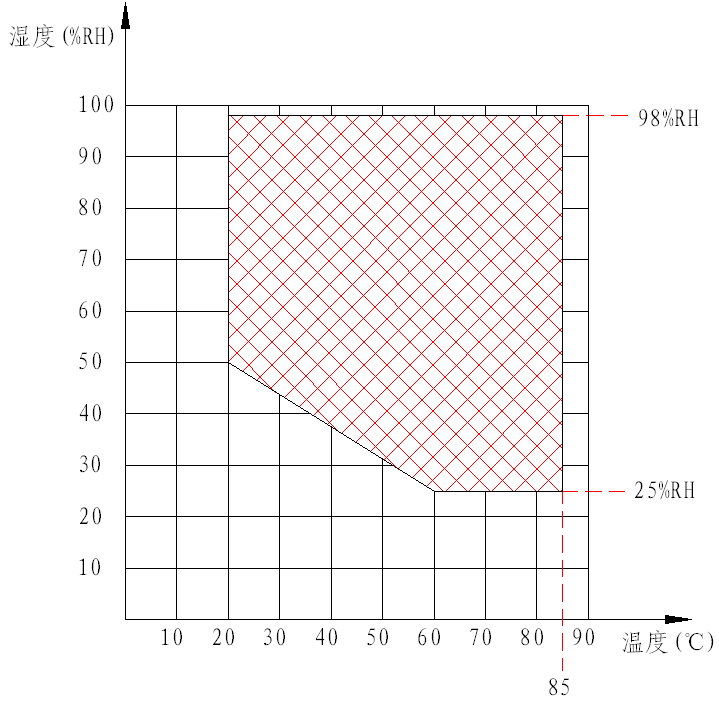

Humidity Controllable Range Diagram (No Active Wet and Thermal Load)

-

Relative Humidity Deviation±3.0%RH (Humidity>75%RH); ±5.0%RH (Humidity≤75%RH)

-

Meet Testing Method

GB/T 2423.1-2008 Testing Method of Low Temperature Ab

GB/T 2423.2-2008 Testing Method of High Temperature Bb

GJB 150.3A-2009 High Temperature Test

GJB 150.4A-2009 Low Temperature Test

GB/T 2423.3-2006 Constant Damp and Heat Testing Method Cab

GB/T 2423.4-2008 Alternating Damp and Heat Test Method Db

GJB 150.9A-2009 Damp and Heat Testing

GB/T 10586-2006 Technical Conditions for Damp and Heat Test Chamber

GB/T 10592-2008 Technical conditions of high and low temperature test chamber

(Load is not greater than 35kg / m3 steel heat capacity. There is no active wet and heat load during damp and heat testing.)

-

Structure Characteristics

-

Thermal Insulation Enclosure Structure

Outer wall material: High quality cold rolled steel plate with plastic spraying and paint baking treatment on the surface.

Inner wall material: Stainless steel plate SUS304.

Box insulation material: rigid polyurethane foam and glass wool (insulation thickness: 100mm)

Door insulation material: Glass wool.

-

Air Conditioning ChannelCentrifugal fan, heater, evaporator (also dehumidifier), humidifier, etc.

-

Standard Configuration of Test Chamber

Lead hole (multiplicable): φ100mm with 2 lead hole.

(Equipped with soft rubber plugs. One on the left side and the other one on the right side of the box.)

Casters: 4个(With adjusting foot.)

Observation Window: Multi layer hollow electric heating film heating anti fog observation window (located on the door).

Visual Range: About 230×270 mm (wide*high). The glass is equipped with electric mist removal, which can provide the best observation sight line.

Floodlight: 1;

Sample rack (can be added): Two layers of high temperature resistant electrical insulation sample rack. Bearing capacity (uniform distribution): 10kg / layer (the cumulative total bearing capacity of samples in the box shall not exceed 40kg).

-

Door

Single hinged door (left hinge, right handle), equipped with observation window and lighting.

Window frame / door frame anti condensation electric heating device. Double layer silicone rubber sealing strip.

-

Control PanelController display screen, overtemperature protection setter, etc.

-

Refrigeration Unit Room

Refrigeration Unit, Water Tray and Drainage Hole;

Condensing Fan, Lifting Water Pump and Water Storage Tank.

-

Power Distribution Control Cabinet

Main Power Leakage Circuit Breaker (One), Distribution Board (One), Exhaust Fan (One), Ethernet Physical Interface (One);

Temperature and Humidity Controller, AC Contactor, Circuit Breaker, Thermal Relay

Temperature limiting protector, solid state relay and transformer, etc.

-

Heater

Ni Cr alloy electric heating wire heater;

Heater control mode: contactless periodic pulse width modulation, SSR (solid state relay).

-

Humidifier

Stainless steel armored heater;

Heater control mode: contactless periodic pulse width modulation, SSR (solid state relay);

Water level control device, heater anti dry burning device.

-

Refrigeration System

-

Operation ModeMechanical compression single-stage refrigeration mode.

-

Refrigeration Compressor"Taikang" fully enclosed compressor imported from France

-

Main Refrigeration ComponentsExpansion valve, pressure controller, drying filter, refrigeration solenoid valve, liquid reservoir, oil separator, etc.

-

EvaporatorFinned tube heat exchanger (also used as dehumidifier).

-

CondenserAir cooled type: finned tube heat exchanger.

-

Throttling DeviceExpansion Valve / Capillary

-

Refrigerator Control ModeControl system automatically adjusts the operating conditions of the refrigeration unit compressor return air cooling circuit according to the test conditions.

-

RefrigerantR404A (Ozone Wastage Index is 0)

-

Welding TechnologyNitrogen filled in order to protect welding.

-

Control System

-

Controller ModelProfessional Temperature and Humidity Controller

-

MonitorHD color LCD touch screen

-

Operation ModeProgram Mode and Setting Mode

-

Setting ModeColor, Touch, Man-machine Interactive, Chinese/ English Interface

-

Control Mode

Anti integral saturation PID;

BTHC balance temperature and humidity control mode.

-

Temperature and Humidity Measurement MethodClass A armored PT100 sensor

-

Display Accuracy

Temperature: 0.01℃; Humidity: 0.1%RH; Time: 1min.

-

Overtemperature ProtectionIndependent overtemperature protector will protect the shutdown and send an alarm signal when the working room temperature exceeds the temperature set by the protection device.

-

Water Supply System

-

Water Supply ModeWater Pump Lifting

-

Location of Water Supply UnitFront water tank, drawer type water filling.

-

Water Supply Quality RequirementsResistivity≥500Ω·m

-

safety Protection Unit

-

Refrigeration SystemCompressor Overheating, Compressor Overload, Compressor Overpressure, Condensate Fan Overheating

-

Humidification System

Humidification heat pipe dry burning, abnormal water supply and drainage.

-

Test ChamberAdjustable overtemperature, blower motor overload and overheating.

-

Others

Main power supply phase sequence and phase loss protection, leakage protection, overload and short circuit protection, power failure recovery protection.

-

Other Configurations

-

Power CableOne Five Core Cable (Three-Phase Four Wire + Protective Ground Wire)

-

Main Power Leakage Circuit BreakerThree phase four wire and protective ground wire.

-

產品

小電流電芯測試儀產品型號CT-4008T-5V10mA/20mA/50mACT-4000三量程mA設備滿足0.05%FS精度,DCIR測試,dQ/dV微分容量曲線, μ A級電流組織,三電極測試。 主要面向各研究機構和高校等。 應用領域:真無線藍牙耳機,扣式電池測試,資料研究。

CT-4008Q-5V100mACT-4000四量程mA設備滿足0.01%FS精度,DCIR測試,dQ/dV微分容量曲線, μA級電流組織,三電極測試。 主要面向各研究機構和高校等。 應用於:真無線藍牙耳機測試,扣式電池測試,資料研究。

CT-4008Q-5V100mACT-4000四量程mA設備滿足0.01%FS精度,DCIR測試,dQ/dV微分容量曲線, μA級電流組織,三電極測試。 主要面向各研究機構和高校等。 應用於:真無線藍牙耳機測試,扣式電池測試,資料研究。 CT-4008-mA/5V6A/5V12A超級電容測試系統是NEWARE公司針對超級電容測試開發的一款分析與診斷系統。 系統分為硬體和軟件兩部分,硬體部分由測試儀器、測試夾具、及PC機等組成,可以測試各種類型超級電容在在不同測試要求下的效能。 系統廣泛應用於超級電容的研發、生產、品檢等環節,具有高性價比、高精度、高集成度等優點。

CT-4008-mA/5V6A/5V12A超級電容測試系統是NEWARE公司針對超級電容測試開發的一款分析與診斷系統。 系統分為硬體和軟件兩部分,硬體部分由測試儀器、測試夾具、及PC機等組成,可以測試各種類型超級電容在在不同測試要求下的效能。 系統廣泛應用於超級電容的研發、生產、品檢等環節,具有高性價比、高精度、高集成度等優點。 CT-4000-5V0.6A/1A3C Digital Cell Testing System: Service for True Wireless Stereo (TWS) Battery Testing,0.05%FS accuracy,3 Range, three-electrode system test, and so on.

CT-4000-5V0.6A/1A3C Digital Cell Testing System: Service for True Wireless Stereo (TWS) Battery Testing,0.05%FS accuracy,3 Range, three-electrode system test, and so on. 3C数位電芯測試儀產品型號CT-4008T-5V6A(3 Ranges)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard.

3C数位電芯測試儀產品型號CT-4008T-5V6A(3 Ranges)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard. CT-4008Q-5V6A (4 Ranges)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard.

CT-4008Q-5V6A (4 Ranges)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard. CT-4008T-5V12A (3 Range)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard.

CT-4008T-5V12A (3 Range)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard. CT-4008Q-5V12A (4 Range)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard.

CT-4008Q-5V12A (4 Range)The model CT-4008-5V6A can be configured with multi-current range channels, which have a current control range of 0.5mA to 0.1A, 0.1A to 3A, 3A to 6A as standard. CT-5008-5V12AThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

CT-5008-5V12AThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. SMB智慧電池測試儀產品型號CE-5008-10V20A-SMB 3C Intelligence Cell Testing CE-5008-20V10A-SMB Laptop Battery Testing CE-5008-24V10A-SMB Laptop Battery Testing CE-5008-24V15A-SMB Laptop Battery Testing CE-5008-20V30A-SMB Intelligence Battery Testing for Electric Tools CT-9008-5V6A-SMB Wearable intelligence battery testing System CT-9008-5V6.5A-SMB Wearable intelligence battery testing System CT-9008-5V12A-T-SMB Wearable intelligence battery testing SystemCE-5008-10V20A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

SMB智慧電池測試儀產品型號CE-5008-10V20A-SMB 3C Intelligence Cell Testing CE-5008-20V10A-SMB Laptop Battery Testing CE-5008-24V10A-SMB Laptop Battery Testing CE-5008-24V15A-SMB Laptop Battery Testing CE-5008-20V30A-SMB Intelligence Battery Testing for Electric Tools CT-9008-5V6A-SMB Wearable intelligence battery testing System CT-9008-5V6.5A-SMB Wearable intelligence battery testing System CT-9008-5V12A-T-SMB Wearable intelligence battery testing SystemCE-5008-10V20A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. CE-5008-20V10A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

CE-5008-20V10A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. CE-5008-24V10A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

CE-5008-24V10A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. CE-5008-24V15A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

CE-5008-24V15A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. CE-5008-20V30A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc.

CE-5008-20V30A-SMBThis equipment is the accumulation of 20 years' experience in the field of precision measurement, and integrates the latest generation of energy-saving inverter technology. It has the communication function of SMBus and I2C. What's more, it is suitable for testing 2-6 strings of battery packs in the application of notebook , tablet, mobile phone , electric tool, Small UAV, etc. CT-9008-5V6A-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles.

CT-9008-5V6A-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles. CT-9008-5V6.5A-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles.

CT-9008-5V6.5A-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles. CT-9008-5V12A-T-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles.

CT-9008-5V12A-T-SMBCT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles. 動力電芯測試儀產品型號CE-4000Application: Power cell formation, grading and cycle life testing; Advantages: Improving energy utilization efficiency and reducing production energy consumption. Mainly support: Battery manufacturers, new energy vehicle manufacturers.

動力電芯測試儀產品型號CE-4000Application: Power cell formation, grading and cycle life testing; Advantages: Improving energy utilization efficiency and reducing production energy consumption. Mainly support: Battery manufacturers, new energy vehicle manufacturers. CT-4000CT-4000 supports some testings as follow: EV battery pulse charge/discharge, DCIR(Direct Current Internal Resistance), cycle life and rate.CT-4000 mainly applies for institutions, colleges and universities and EV battery manufacturers.

CT-4000CT-4000 supports some testings as follow: EV battery pulse charge/discharge, DCIR(Direct Current Internal Resistance), cycle life and rate.CT-4000 mainly applies for institutions, colleges and universities and EV battery manufacturers. CT-8000Based on Neware fifth-generation testing system.Mainly used in Power battery condition simulation ,Pulse charging and discharging, Cycle Life, Rate of charge and discharge.

CT-8000Based on Neware fifth-generation testing system.Mainly used in Power battery condition simulation ,Pulse charging and discharging, Cycle Life, Rate of charge and discharge. CE-8000Based on Neware fifth-generation testing system.Mainly used in Power battery condition simulation ,Pulse charging and discharging, Cycle Life, Rate of charge and discharge.

CE-8000Based on Neware fifth-generation testing system.Mainly used in Power battery condition simulation ,Pulse charging and discharging, Cycle Life, Rate of charge and discharge. PACK模組測試儀產品型號CE-4000CT-4000, based on Neware 4th generation testing system, entered into market in 2008. CT-4000 supports some testings as follow: EV battery pulse charge/discharge, DCIR(Direct Current Internal Resistance), cycle life and rate.

PACK模組測試儀產品型號CE-4000CT-4000, based on Neware 4th generation testing system, entered into market in 2008. CT-4000 supports some testings as follow: EV battery pulse charge/discharge, DCIR(Direct Current Internal Resistance), cycle life and rate. CE-6000n(High frequency isolation10V~120V)It has the characteristics of high dynamic response speed, high stability precision and multi-channel flexible configuration which also supports pulse test, cycle life test and simulation test. The system has the function of multi-channel input and energy recovery, which can save a lot of electric energy consumed in the process of charging and discharging.

CE-6000n(High frequency isolation10V~120V)It has the characteristics of high dynamic response speed, high stability precision and multi-channel flexible configuration which also supports pulse test, cycle life test and simulation test. The system has the function of multi-channel input and energy recovery, which can save a lot of electric energy consumed in the process of charging and discharging. CE-6000(Tower)It has the characteristics of high dynamic response speed, high stability precision and multi-channel flexible configuration which also supports pulse test, cycle life test and simulation test. The system has the function of multi-channel input and energy recovery, which can save a lot of electric energy consumed in the process of charging and discharging.

CE-6000(Tower)It has the characteristics of high dynamic response speed, high stability precision and multi-channel flexible configuration which also supports pulse test, cycle life test and simulation test. The system has the function of multi-channel input and energy recovery, which can save a lot of electric energy consumed in the process of charging and discharging. 高性能電芯測試儀產品型號CT-9002CT-9002 is full of heavyweight functions. It is very light and thin. The height is one third of 9004G and 9008. It also has the performance of 0.02% accuracy, 1000Hz data acquisition frequency, 4 range and so on.

高性能電芯測試儀產品型號CT-9002CT-9002 is full of heavyweight functions. It is very light and thin. The height is one third of 9004G and 9008. It also has the performance of 0.02% accuracy, 1000Hz data acquisition frequency, 4 range and so on. CT-9004GCT-9004, as our latest battery testing system, brings you up-to-date, sophisticated hardware technology and brand-new software experience. It's characterized with a maximum data acquisition frequency of 1000Hz, 4 automated-switch output ranges, 0.02% accuracy and a minimum pulse width of 400μs.

CT-9004GCT-9004, as our latest battery testing system, brings you up-to-date, sophisticated hardware technology and brand-new software experience. It's characterized with a maximum data acquisition frequency of 1000Hz, 4 automated-switch output ranges, 0.02% accuracy and a minimum pulse width of 400μs. CT-9008CT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles.

CT-9008CT-9008 offers ultra-high precision charge/discharge testing systems for basic charge/discharge cycling, and simulating complex realworld applications such as drive profiles,cycle life tests, DCIR DC internal resistance tests or other custom profiles. 環境試驗箱產品型號MGDW Series (Standard) High and Low Temperature Environmental Chamber MGDW Series (Humidity) High and Low Temperature Environmental Chamber MGDW Series (Flameproof) High and Low Temperature Environmental Chamber (Flameproof) MGDW Series (Flameproof and Humidity) High and Low Temperature Environmental Chamber MGW Series (Standard) High Temperature Environmental Chamber MGW Series (Flameproof) High Temperature Environmental Chamber (Flameproof) MHW-25-S Desktop Temperature Test Chamber for Semiconductor Refrigeration MHWX-2000 (Refrigerate via Compressor) Temperature Test Chamber MHW-480 (Refrigerate via All-in-One Compressor) Temperature Test Chamber MIHW-200-160CH (Refrigerate via Compressor) Temperature Test Chamber MFB-220/350/500-2K Double Location Flameproof Chamber MFB-220-20K Multi Location Flameproof ChamberMGDW Series (Standard)NEWARE battery charge and discharge test system realizes integrated operation and collaborative work through BTS upper computer control system, so as to maximize the battery characteristics and functions.MGDW Series (Humidity)High and Low Temperature Environmental Chamber (Humidity)

環境試驗箱產品型號MGDW Series (Standard) High and Low Temperature Environmental Chamber MGDW Series (Humidity) High and Low Temperature Environmental Chamber MGDW Series (Flameproof) High and Low Temperature Environmental Chamber (Flameproof) MGDW Series (Flameproof and Humidity) High and Low Temperature Environmental Chamber MGW Series (Standard) High Temperature Environmental Chamber MGW Series (Flameproof) High Temperature Environmental Chamber (Flameproof) MHW-25-S Desktop Temperature Test Chamber for Semiconductor Refrigeration MHWX-2000 (Refrigerate via Compressor) Temperature Test Chamber MHW-480 (Refrigerate via All-in-One Compressor) Temperature Test Chamber MIHW-200-160CH (Refrigerate via Compressor) Temperature Test Chamber MFB-220/350/500-2K Double Location Flameproof Chamber MFB-220-20K Multi Location Flameproof ChamberMGDW Series (Standard)NEWARE battery charge and discharge test system realizes integrated operation and collaborative work through BTS upper computer control system, so as to maximize the battery characteristics and functions.MGDW Series (Humidity)High and Low Temperature Environmental Chamber (Humidity) MGDW Series (Flameproof)High and Low Temperature Environmental Chamber (Flameproof)

MGDW Series (Flameproof)High and Low Temperature Environmental Chamber (Flameproof) MGDW Series (Flameproof and Humidity)High and Low Temperature Environmental Chamber (Flameproof and Humidity)

MGDW Series (Flameproof and Humidity)High and Low Temperature Environmental Chamber (Flameproof and Humidity) MGW Series (Standard)Neware research high temperature chamber independently and own independent property rights. It is a reliability equipment that can be used for battery testing in the new energy industry. It can provide the high temperature simulated climate environment for battery charging and discharging.

MGW Series (Standard)Neware research high temperature chamber independently and own independent property rights. It is a reliability equipment that can be used for battery testing in the new energy industry. It can provide the high temperature simulated climate environment for battery charging and discharging. MGW Series (Flameproof)Neware research high temperature chamber independently and own independent property rights. It is a reliability equipment that can be used for battery testing in the new energy industry. It can provide the high temperature simulated climate environment for battery charging and discharging.

MGW Series (Flameproof)Neware research high temperature chamber independently and own independent property rights. It is a reliability equipment that can be used for battery testing in the new energy industry. It can provide the high temperature simulated climate environment for battery charging and discharging. MHW-25-SLess than 0.2 ㎡ of floor space to satisfy your laboratory battery testing needs.

MHW-25-SLess than 0.2 ㎡ of floor space to satisfy your laboratory battery testing needs. MHWX-2000 (Refrigerate via Compressor)Temperate Chamber is mainly used for the temperature test of coin batteries and 3C pouch cell batteries. It has the characteristics of space utilization maximization (160 coin batteries can be placed in), integrated operation in BTS upper computer control, etc. Mainly for research institutions, universities and battery production enterprise experimental center.

MHWX-2000 (Refrigerate via Compressor)Temperate Chamber is mainly used for the temperature test of coin batteries and 3C pouch cell batteries. It has the characteristics of space utilization maximization (160 coin batteries can be placed in), integrated operation in BTS upper computer control, etc. Mainly for research institutions, universities and battery production enterprise experimental center. MHW-480 (Refrigerate via All-in-One Compressor)Temperate Chamber is mainly used for the temperature test of coin batteries and 3C pouch cell batteries.

MHW-480 (Refrigerate via All-in-One Compressor)Temperate Chamber is mainly used for the temperature test of coin batteries and 3C pouch cell batteries. MIHW-200-160CH (Refrigerate via Compressor)MIHW-200-160CH 一体机压缩机制冷恒温试验箱,主要用于扣式电池和3C的软包电池温度测试。具有设备空间利用最大化(可放置160个扣式电池)、BTS上位机控制一体化操作等特点。主要面向各研究机构、高校和电池生产企业实验中心。

MIHW-200-160CH (Refrigerate via Compressor)MIHW-200-160CH 一体机压缩机制冷恒温试验箱,主要用于扣式电池和3C的软包电池温度测试。具有设备空间利用最大化(可放置160个扣式电池)、BTS上位机控制一体化操作等特点。主要面向各研究机构、高校和电池生产企业实验中心。 MFB-220/350/500-2KMFB-220/350/500-2K Double Location Flameproof Chamber

MFB-220/350/500-2KMFB-220/350/500-2K Double Location Flameproof Chamber MFB-220-20KMFB-220-20K Multi Location Flameproof Chamber

MFB-220-20KMFB-220-20K Multi Location Flameproof Chamber 電芯夾具產品型號A705-P-QS-B Polymer Clamps PCB Coin Cell Clamps PCB Coin Cell Clamps A707-BU-27C+ / A503-PVC-BU- Crocodile Clamps A705-P5-45B+(-) 1250-3 Polymer Clamps 10A Polymer Clamps (With slide rail) A705-P-QS-10A A705-T-P-200A+(-) Toggle Clamps(200A) 6545 Polymer Clamps Polymer Clamps (Positive and Negative Integration) Bakelite Clamps (16CH) Bakelite Clamps A705-P-QS-10A M2545-3 Polymer Clamps A211-BTS-4S-1U Upper and Lower ClampsA705-P-QS-BA705-P-QS-B: Polymer Clamps

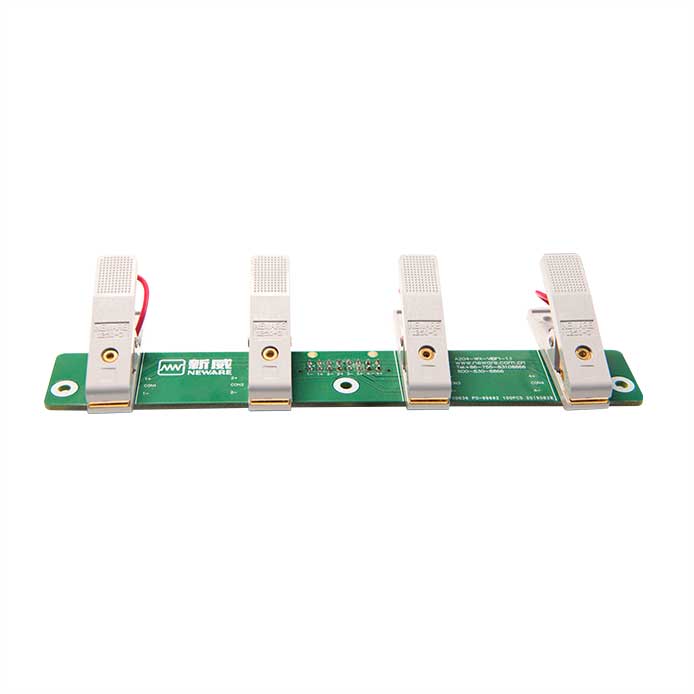

電芯夾具產品型號A705-P-QS-B Polymer Clamps PCB Coin Cell Clamps PCB Coin Cell Clamps A707-BU-27C+ / A503-PVC-BU- Crocodile Clamps A705-P5-45B+(-) 1250-3 Polymer Clamps 10A Polymer Clamps (With slide rail) A705-P-QS-10A A705-T-P-200A+(-) Toggle Clamps(200A) 6545 Polymer Clamps Polymer Clamps (Positive and Negative Integration) Bakelite Clamps (16CH) Bakelite Clamps A705-P-QS-10A M2545-3 Polymer Clamps A211-BTS-4S-1U Upper and Lower ClampsA705-P-QS-BA705-P-QS-B: Polymer Clamps PCB Coin Cell ClampsPCB Coin Cell Clamps

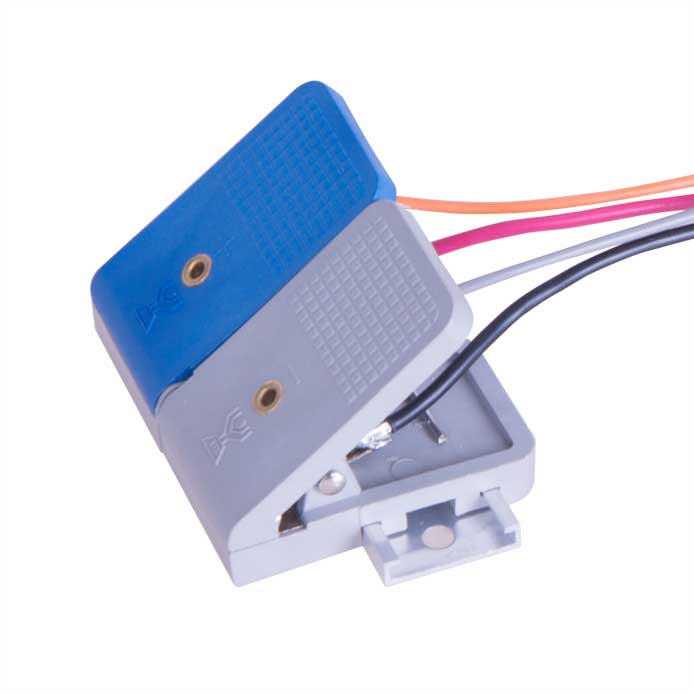

PCB Coin Cell ClampsPCB Coin Cell Clamps A707-BU-27C+ / A503-PVC-BU-Crocodile Clamps

A707-BU-27C+ / A503-PVC-BU-Crocodile Clamps A705-P5-45B+(-)A705-P5-45B+(-) 1250-3 Polymer Clamps10A Polymer Clamps (With slide rail)10A Polymer Clamps (With slide rail)

A705-P5-45B+(-)A705-P5-45B+(-) 1250-3 Polymer Clamps10A Polymer Clamps (With slide rail)10A Polymer Clamps (With slide rail) A705-T-P-200A+(-)Toggle Clamp is used to test high current polymer clamps, such as 200A, 300A.

A705-T-P-200A+(-)Toggle Clamp is used to test high current polymer clamps, such as 200A, 300A. 6545 Polymer Clamps6545 Polymer Clamps (Positive and Negative Integration)

6545 Polymer Clamps6545 Polymer Clamps (Positive and Negative Integration) Bakelite Clamps (16CH)Bakelite Clamps (16CH)

Bakelite Clamps (16CH)Bakelite Clamps (16CH) A705-P-QS-10AA705-P-QS-10AM,2545-3 Polymer Clamps

A705-P-QS-10AA705-P-QS-10AM,2545-3 Polymer Clamps A211-BTS-4S-1UA211-BTS-4S-1U: Upper and Lower Clamps

A211-BTS-4S-1UA211-BTS-4S-1U: Upper and Lower Clamps 19'' Cell Tray19'' Cell Tray24'' Cell Tray24'' Cell TrayA211-BTS-4S-1U-ZWJThe 4 series Middle-subordinate Machine is the Lower-subordinate Machine and the computer hub . It can be used in many low current 4 series equipment, such as: mA, 5V6A, 5V12A.

19'' Cell Tray19'' Cell Tray24'' Cell Tray24'' Cell TrayA211-BTS-4S-1U-ZWJThe 4 series Middle-subordinate Machine is the Lower-subordinate Machine and the computer hub . It can be used in many low current 4 series equipment, such as: mA, 5V6A, 5V12A. BTS Auto CaliBTS Auto Cali (Calibration)

BTS Auto CaliBTS Auto Cali (Calibration) CA-4008-1U-VT-EVT (VT)AUX testers are designed for gathering the data of single cells’ voltage and temperature, to realize real-time monitoring and protection in battery module or pack testing.

CA-4008-1U-VT-EVT (VT)AUX testers are designed for gathering the data of single cells’ voltage and temperature, to realize real-time monitoring and protection in battery module or pack testing. BVIR二次电池电压内阻测试仪BVIR二次电池电压内阻测试仪,专门为二次电池(包括铅酸、镍镉、镍氢、锂离子、锂聚合物电池)设计的高精度测量仪器。

BVIR二次电池电压内阻测试仪BVIR二次电池电压内阻测试仪,专门为二次电池(包括铅酸、镍镉、镍氢、锂离子、锂聚合物电池)设计的高精度测量仪器。

-

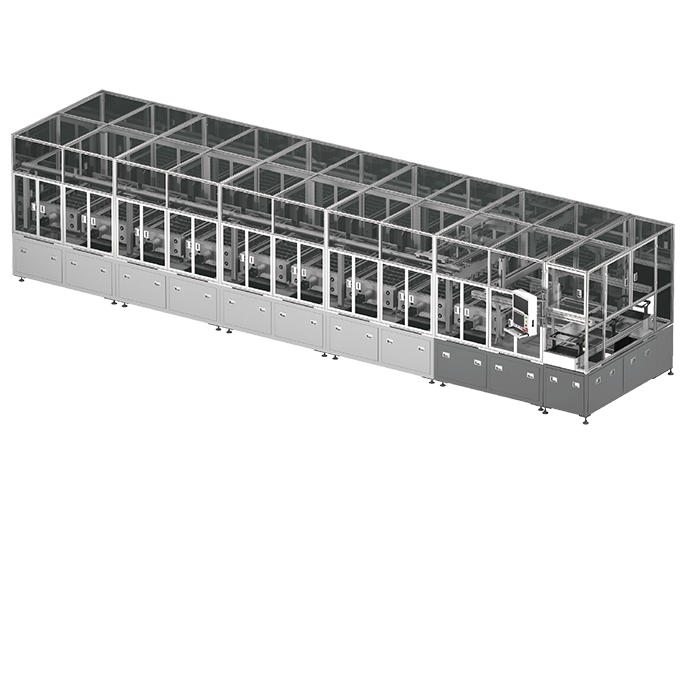

解決方案

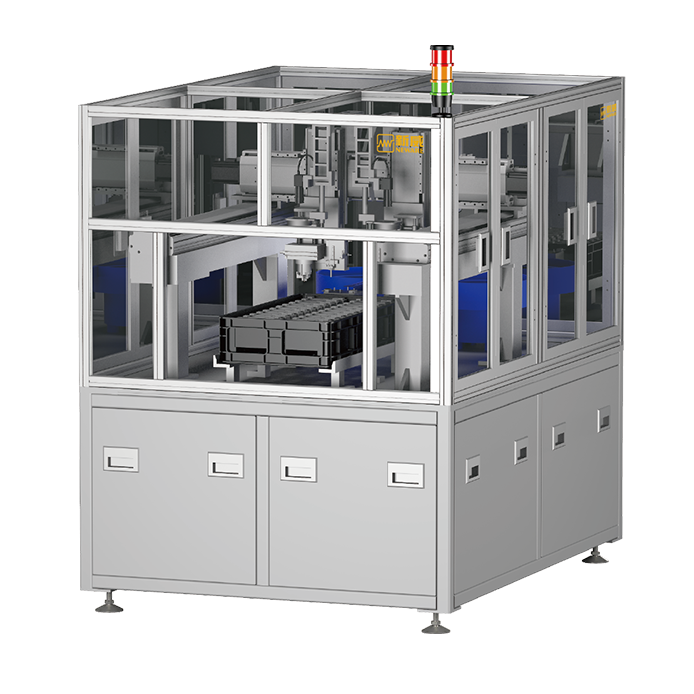

OCV/IR Testing and Sorting EquipmentMeasuring the voltage and internal resistance of the cell; Cells output in grades; Reuse the pallet.

Nail EvulsionCells input by RGV; Pallet located automatically; Nails pull out from the injecting hole automatically by manipulator; Cells output by RGV.

Nail EvulsionCells input by RGV; Pallet located automatically; Nails pull out from the injecting hole automatically by manipulator; Cells output by RGV. Nail InsertionNail Insertion Machine, Cells input by RGV; Pallet located automatically; Nails insert into the injecting hole automatically by manipulator; Cells output by RGV.

Nail InsertionNail Insertion Machine, Cells input by RGV; Pallet located automatically; Nails insert into the injecting hole automatically by manipulator; Cells output by RGV. Rest ShelfRest Shelf, The shelve is made by steel; Convenient transportation and installation. Meets the need of long-term automatic operation of tridimensional storage system.

Rest ShelfRest Shelf, The shelve is made by steel; Convenient transportation and installation. Meets the need of long-term automatic operation of tridimensional storage system. 軟包聚合物電芯自動化解決方案瀏覽OCV/IR TesterThe tester measure the voltage/ internal resistance of cells, store and upload the data to the database. The tester is composed of control circuit module, test module, electric actuating unit, and sensing device module, etc.

軟包聚合物電芯自動化解決方案瀏覽OCV/IR TesterThe tester measure the voltage/ internal resistance of cells, store and upload the data to the database. The tester is composed of control circuit module, test module, electric actuating unit, and sensing device module, etc. Grading MachineGrading Machine - Solution of Pouch Cell

Grading MachineGrading Machine - Solution of Pouch Cell Formation Machine with Heating & PressingFormation Machine with Heating & Pressing - Solution of Pouch Cell

Formation Machine with Heating & PressingFormation Machine with Heating & Pressing - Solution of Pouch Cell Rest ShelfThe shelve is made by steel; Convenient transportation and installation. Meets the need of long-term automatic operation of tridimensional storage system.

Rest ShelfThe shelve is made by steel; Convenient transportation and installation. Meets the need of long-term automatic operation of tridimensional storage system. 圓柱電芯自動化解決方案瀏覽PACK自動化解決方案瀏覽

圓柱電芯自動化解決方案瀏覽PACK自動化解決方案瀏覽 -

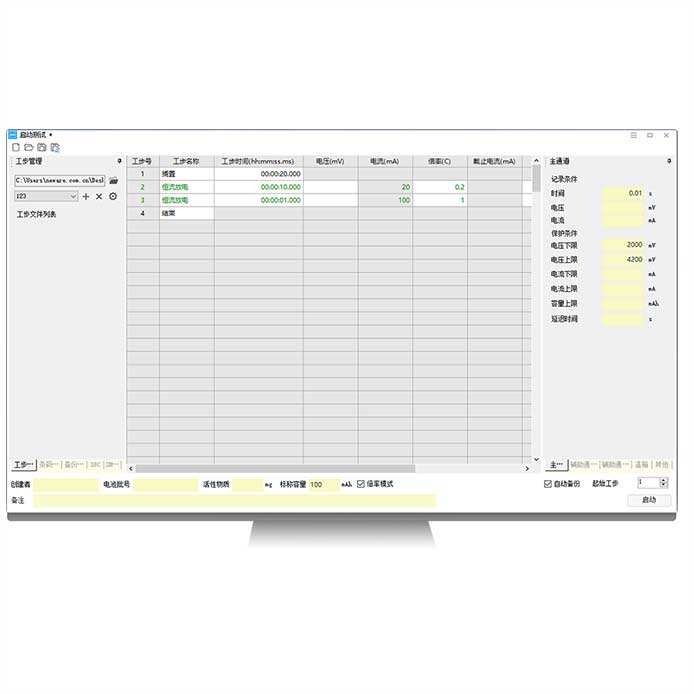

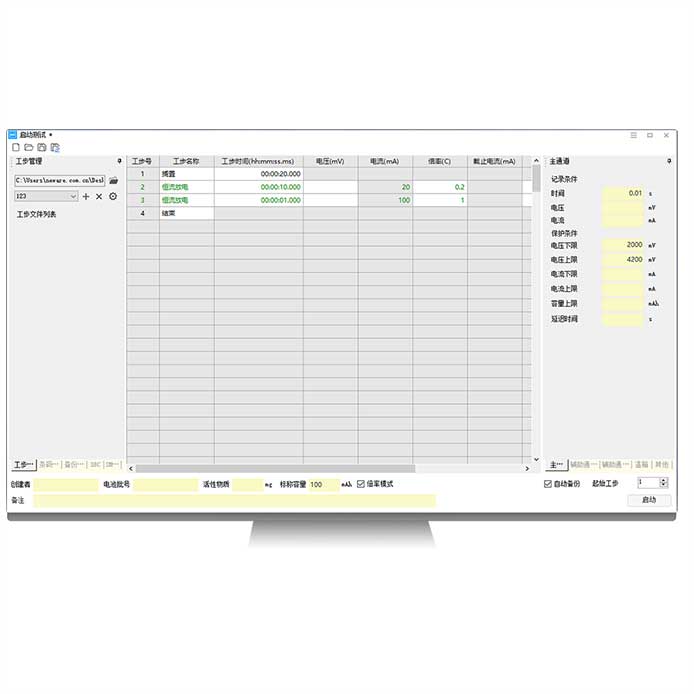

軟件

BTS電池資訊管理hile providing excellent battery testing equipment for customers, according to customers' needs and the characteristics of battery industry, we have successfully developed a complete software solution for the battery industry enterprises.

LIMS智慧管理系統LIMS Realizes Lean Laboratory Management

LIMS智慧管理系統LIMS Realizes Lean Laboratory Management 資料分析Battery Data Science in the Future; Data Oriented, Data Science; Super Calculation Power;

資料分析Battery Data Science in the Future; Data Oriented, Data Science; Super Calculation Power; BIS製造企業生產執行系統BATMES (Battery Manufacturing Execution System), the core software platform, services for battery production enterprises.

BIS製造企業生產執行系統BATMES (Battery Manufacturing Execution System), the core software platform, services for battery production enterprises.

- 服務

- 下載

-

產品TWS耳機電芯測試儀3C数位電芯測試儀SMB智慧電池測試儀環境試驗箱MGDW Series (Standard)MGDW Series (Humidity)MGDW Series (Flameproof)MGDW Series (Flameproof and Humidity)MGW Series (Standard)MGW Series (Flameproof)MHW-25-SMHWX-2000 (Refrigerate via Compressor)MHW-480 (Refrigerate via All-in-One Compressor)MIHW-200-160CH (Refrigerate via Compressor)MFB-220/350/500-2K MFB-220-20K電芯夾具中比特機校準工裝BFGS & BVIR

-

解決方案圓柱電芯自動化解決方案PACK自動化解決方案

-

軟件BTS電池資訊管理系統NEWARE AIBIS製造企業生產執行系統

-

服務

-

Downloads

Global - English

Global - English